Lanning Smith Studios

I found out about Lanning Smith Studios in Spring semester of my junior year from a former classmate of mine, Katya Villano (Class of 2016, Painting). She described her work at a small fabrication company which primarily specialized in woodworking, in addition to a variety of larger construction and other processes. Overall she really enjoyed the work and spoke highly of the people, and mentioned that two current IS seniors had previously interned there in the summer of 2016. I became especially interested because it seemed this organization was open to people with relatively little experience so long as they had drive and interest. Soon after, I spoke with both Chelsea Lee and Jenna Staffieri (Class of 2017, IS) about their respective experiences. While the projects were often for big name clients, they were still able to enter the shop as a learning environment. I quickly sent out an email with my cover letter and resume.

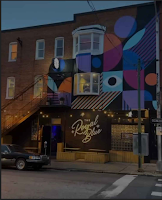

When I first met with Kyle, he explained that several years ago, after graduating from MICA, he and his partner Josh established Lanning Smith and have since worked out a split system. Josh lives in New York and primarily handles the business side of the operation-working through their small location in Brooklyn, meeting and negoatiting with clients. The Baltimore location is the fabrication shop, with a small office and shop space upstairs, and a much larger area in the basement for bigger construction and works. During my time there I was able to work fairly closely with everyone in the shop because of its small size. Kyle and I were the only ones in the shop on Mondays, which is when I was able to see a bit more of how Kyle manages the projects from design, client back and forth, shipping, etc. I mainly worked with two other coworkers in the shop; Sutton Demlong (Rhinehart ‘16) and Katya, both of whom were incredibly helpful and patient, while also trusting in my abilities. I always felt comfortable asking clarifying questions but never felt patronized for not knowing something. For the majority of my time there, we worked on a variety of retail displays and decorations for an imitation beach shop to be installed at their New York space. There were also bits and pieces of a trade show booth project for a client which we worked on progressively throughout my time there.

Over time, I found myself becoming faster and more exacting in the work I was doing, I felt more comfortable, had to ask fewer questions and trusted my own instincts. I even found that when it came to certain projects, my coworkers would ask me to complete tasks because they felt I might even do it a bit better than they would, which was really exciting and assuring. While I could see tangible improvement in my technical skills, I found that my interpersonal and communication skills also had to improve and adjust according to my environment so as to efficiently work as a team. At the close of my experience, I had discovered how much I really enjoy the shop environment, building things for the sake of building things and honing my skills. I definitely think that working in a fabrication studio is a viable career op on for me, and I plan on maintaining contact with Kyle and the crew at Lanning Smith Studios throughout the course of my senior year for occasional freelance work in the future.