Neighborhood Fiber Co.

My name is Elena Echenique and I am a senior Fiber major. During the Fall of 2018, I was a Dye Assistant Intern for Neighborhood Fiber Co., a company based in Baltimore, Maryland. Before the beginning of the semester, I was on the hunt for an internship to gain experience and skills in the field of fiber arts. I was exploring the Career Development website in search for opportunities when I came across the internship opening at NFC. For some time now I have had a goal to someday own my own yarn business in which I harvest, spin, and dye my own yarn, so when I came across this opportunity, I figured it would teach me some very useful skills that would help me reach my goal.

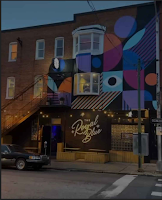

My name is Elena Echenique and I am a senior Fiber major. During the Fall of 2018, I was a Dye Assistant Intern for Neighborhood Fiber Co., a company based in Baltimore, Maryland. Before the beginning of the semester, I was on the hunt for an internship to gain experience and skills in the field of fiber arts. I was exploring the Career Development website in search for opportunities when I came across the internship opening at NFC. For some time now I have had a goal to someday own my own yarn business in which I harvest, spin, and dye my own yarn, so when I came across this opportunity, I figured it would teach me some very useful skills that would help me reach my goal.The company itself is a locally based business that purchases the winded and un-dyed yarn from a nearby manufacturer and then produces its own colors through a variety of dye recipes. The yarn is then hand-dyed and sold in a single location. For this internship, I was part of the hand-dying process as an assistant to my supervisor, Jenelle, who is the Dye Technician at the company. Together, our daily tasks were to read through the "Dye List" which contained a list of the types of yarn, what colors they needed to be dye to, and the amount of each that needed to be completed each day. We would then rinse out the pots containing yarn from the previous day and hang them on the drying racks. Next, we would season the stove by oiling it and turning the burners to a low flame. After we did that, we would soak the yarn we needed to dye as we prepped the pots and mixed the dye we needed.

This was basically what we would do every day, but occasionally there would be some special projects and events I was able to be a part of such as Saturday classes in which customers would come in for private dye lessons. I was also able to be a part of the development of new colors that are now being sold. One of the most exciting events, however, was the Fiber Space event in which we had 50 customers arrive by bus from Virginia and Jenelle and I had 5 hours to custom dye yarn for each one of them. It was extremely hectic but it was so much fun to be able to work with the customers and mix the colors on the spot without any recipes.

I think my biggest take away from this experience is learning about and understanding the production process of hand-dying yarn. Due to this internship, I am now able to have a better grasp of the time and labor required to produce dyed yarn. I feel like I can now take the information and skills that I have learned and apply them to further myself in my career goals.